Water treatment process

Shoalhaven Water supplies fresh clean water to more than 52,000 homes and businesses. Our reticulated area extends from Berry in the north to Lake Tabourie in the south.

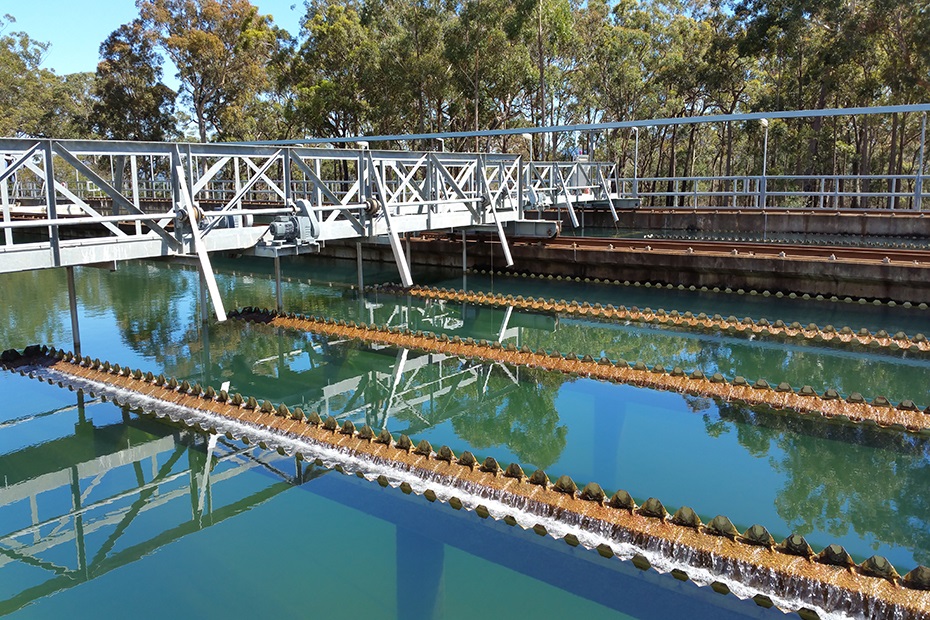

The Bamarang water treatment plant is our largest treatment facility and processes up to 75ML (million litres) of water each day.

Treatment process

Our water treatment process includes:

Coagulation

When water from Bamarang Dam enters the treatment plant, a chemical called Aluminium Sulphate (Alum) is added.

This helps the minute dirt particles meet up and stick together to form clumps which then settle in readiness for the sedimentation process. The small particles including dirt and leaves are called 'flocs'.

Flocculation

By adding polyelectrolytes to the water, the flocs gently sink to the bottom of the tank and become sediment.

Sedimentation

This sediment that sits on the bottom of the tank is called sludge and must be drained from the tank. The sludge is pumped to a sludge lagoon where it is dried out and taken off-site.

After passing through the sedimentation process the water is then pumped through a filter made from layers of sand and gravel that traps more particles including algae.

By this time the water is becoming a sparkling clean product and this step is often called polishing.

Filtration

The water filtration method basically copies nature by passing the water through various layers of filter material.

The multi-layer filtration, in conjunction with flocculation, and the sedimentation stage, helps remove any remaining particulate matter, including any suspended particles that may be present in the water.

Other parts of the filtration process that also keep the filters and pipes clean are:

- Air Scouring - is where air is forced into the pipes and filters at high pressure to clean and clear them. The air expands the bed of sand and loosens the particles of dirt which float to the surface

- Backwashing - keeps the filters in good working order

When we do routine air scouring and backwashing in the filters, the water used is then piped back to the initial treatment stage.

Chlorination

Chlorination is a form of disinfection and is needed to kill harmful micro-organisms that may be present in water from the rivers and dams.

Our process includes injecting chlorine gas into the water to kill off any bacteria and viruses.

pH correction

Pure water has a neutral pH which is 7 on the pH scale. Impurities in raw water or chemicals used in the treatment process can make water either acidic or alkaline.

Leveling the pH helps minimise corrosion in the distribution system and optimises effectiveness of the chlorine disinfection process.

Fluoridation

Shoalhaven Water fluoridates water in accordance with the NSW Fluoridation of Public Water Supplies Act 1957 and the Fluoridation of Public Water Supplies Regulation 2012.

Fluoride is added to help reduce dental cavities.